UREP-7 Cycle

Funding Agency

Project No

UREP-07-055-2-012

Project Duration

Oct. 2009-Oct. 2010

Total funding

US$20,000; Prof. Nimir portion – US20,000

Students

Sally Nicola (currently with Flour in USA) and Natali Hamad (Currently with TOTAL Chemicals in France)

Project Title

An Approach to the Design of Advanced Fischer-Tropsch Reactor Technology (Phase I)

Project Description

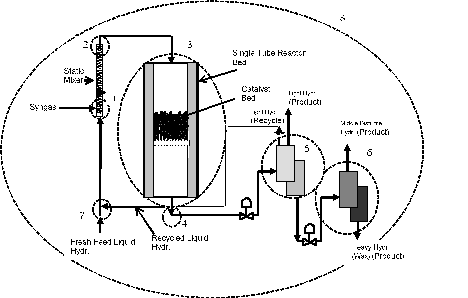

Conducting FTS reactions in supercritical fluid (SCF) media has been demonstrated to have certain advantages over the traditional routes because of the unique characteristics of the supercritical phase (combines the desirable properties of gas-like diffusion along with liquid-like heat transfer and solubility to overcome many of the aforementioned limitations of the current industrial FTS reactors). There are several advantages of operating FTS in SCF media versus operation in conventional media (gas-phase and liquid-phase) : (1) in-situ extraction of heavy hydrocarbons from the catalyst pores resulting from high solubility in the supercritical phase, (2) elimination of interphase transport limitations thus promoting reaction pathways toward the desired products, (3) enhancement of α-olefins desorption that promote the chain growth process prior to secondary reactions, and (4) excellent heat transfer compared to gas-phase reaction that resulted in more long chain products. These advantages resulted in better selectivity towards middle distillate hydrocarbons (diesel fuel), lower selectivity of undesired products such as CH4 and CO2 and longer catalyst life time. Nevertheless, developing

The objectives of this project are to design an advanced reactor system to facilitate supercritical phase FTS operating conditions and to compare this new configuration to existing commercial FBR and SBR reactors.

Major Project Accomplishments

Peer reviewed journal publications, Book chapters

1. Elmalik E., Mogalicherla, A.K, Hamad, N., Nicola, S., Elbashir, N. O. (2010). Simulating Fischer-Tropsch Synthesis Phase Behavior in non-conventional reaction media. Preprint Paper American Chemical Society, Division of Fuel Chemistry, 55 (2); pp. 173-175.

2. Natalie Hamad “Simulation of Fischer Tropsch Synthesis Commercial Reactor Technology” Presented as a Poster in the American Institute of Chemical Engineers 2010 Meeting in Salt-Lake City.

Collaboration

Qatar Shell Research Center