NPRP-EP

Funding Agency

Project No

NPRP-X-100-2-024

Project Duration

Aug 2015 – Nov 2020

Total funding

$4,798,003.19 (Prof. Nimir portion: $2,200,000)

Project Title

Design of Novel Catalysts and Processes for CO2 Conversion from Micro- to Macroscale

Project Collaborators

Project Description

Qatar’s current reserves of natural gas are estimated at 22 trillion cubic meters—the third largest in the world. Qatar has monetized its abundant natural gas reserves to become the “The Gas Processing Capital of the World.” Qatar also ranks highest in CO2 emissions per capita worldwide. Effectively capturing CO2 must go hand-in-hand with either secure storage or conversion to useful products. CO2 and methane are both abundant in Qatar. The outcome of this research project provides a unique opportunity for Qatar to lower CO2 emissions while diversifying the utilization of its natural gas resources for ultra-clean fuels and chemicals.

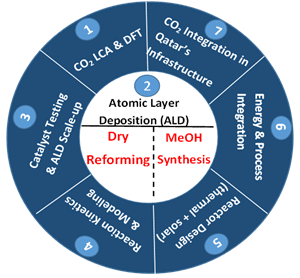

This proposal aims at exploring the potential of novel catalysts and catalytic processes for CO2 conversion whereby CO2 consumption in the process is greater than the CO2 produced at any stage of the process. The focus of this project will be on two major challenges; 1) CO2 assisted natural gas reforming, referred to as dry reforming, which can be integrated with processes for fuel and chemical production; 2) production of a major chemical building block, methanol, from the reaction of H2 with CO2. Success in developing new catalysts and novel technologies for the aforementioned conversions could have

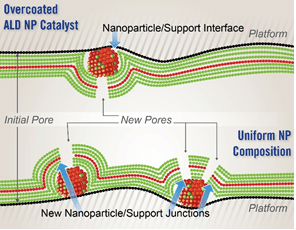

Schematic structure of ultra-high performance catalysts for dry reforming and methanol synthesis synthesized via Atomic Layer Deposition (ALD)

Project Overview

This multi-faceted approach seamlessly spans micro scale investigations (fundamental catalyst synthesis studies, exploratory catalytic conversions via photochemical and thermal pathways and optimizations, and reaction mechanism elucidation via DFT) coupled to macro scale studies (detailed applied research, transitioning the micro-scale studies to reactor bed design and the other technological issues, alongside studies analyzing the CO2 life-cycle to ensure that net CO2 produced is less than the CO2 consumed as raw material). In addition to the aforementioned studies, the effort will address important elements relevant to breakthrough CO2 conversion technologies by also incorporating: 1) reactor scale-up and catalyst synthesis to commercially acceptable scale and 2) Integrating new CO2 conversion processes within existing Qatar process plants.

Major Project Accomplishments (upto date)

Peer reviewed journal publications, Book chapters

1. Gili, A.; Schlicker, L.; Bekheet, M. F.; Görke, O.; Penner, S.; Grünbacher, M.; Götsch, T.; Littlewood, P.; Marks, T. J.; Stair, P. C.; Schomaecker, R; Doran, A.; Selve, S.; Simon, U.; Gurlo, A.; Surface Carbon as a Reactive Intermediate in Dry Reforming of Methane to Syngas on the 5% Ni/MnO Catalyst. ACS Catal. 2018, 8, 8739–8750. (Impact factor: 11.38)

2. S. Afzal, D. Sengupta, A. Sarkar, M. M. El-Halwagi and N. O. Elbashir, “An Optimization Approach to the Reduction of CO2 Emissions for Syngas Production Involving Dry Reforming”, ACS Sustainable Chemistry and Engineering, DOI: 10.1021/acssuschemeng.8b00235, 23 April 2018. (Impact factor 5.95)

3. M.S. Challiwala, M.M. Ghouri, P. Linke, M.M. El-Halwagi, N.O. Elbashir, A combined thermo-kinetic analysis of various methane reforming technologies: Comparison with dry reforming, Journal of CO2 Utilization, Volume 17, 2017, Pages 99-111, ISSN 2212-9820,

4. M.S. Challiwala, M.M. Ghouri, D. Sengupta, M.M. El-Halwagi, N.O. Elbashir, “A Process Integration Approach to the Optimization of CO2 Utilization via Tri-Reforming of Methane”, Antonio Espuña, Moisès Graells and Luis Puigjaner (Editors), Proceedings of the 27th European Symposium on Computer Aided Process Engineering – ESCAPE 27, October 1st – 5th, 2017, Barcelona, Spain © 2017 Elsevier B.V. All rights reserved. Book ISBN: 9780444639653.

5. S. Afzal, D. Sengupta, M. M. El-Halwagi and N. O. Elbashir, “Minimizing CO2 emissions for syngas production units using Dry Reforming of Methane”, Antonio Espuña, Moisès Graells and Luis Puigjaner (Editors), Proceedings of the 27th European Symposium on Computer Aided Process Engineering – ESCAPE 27, October 1st – 5th, 2017, Barcelona, Spain © 2017 Elsevier B.V. All rights reserved. Book ISBN: 9780444639653.

Conference Proceedings & Presentations:

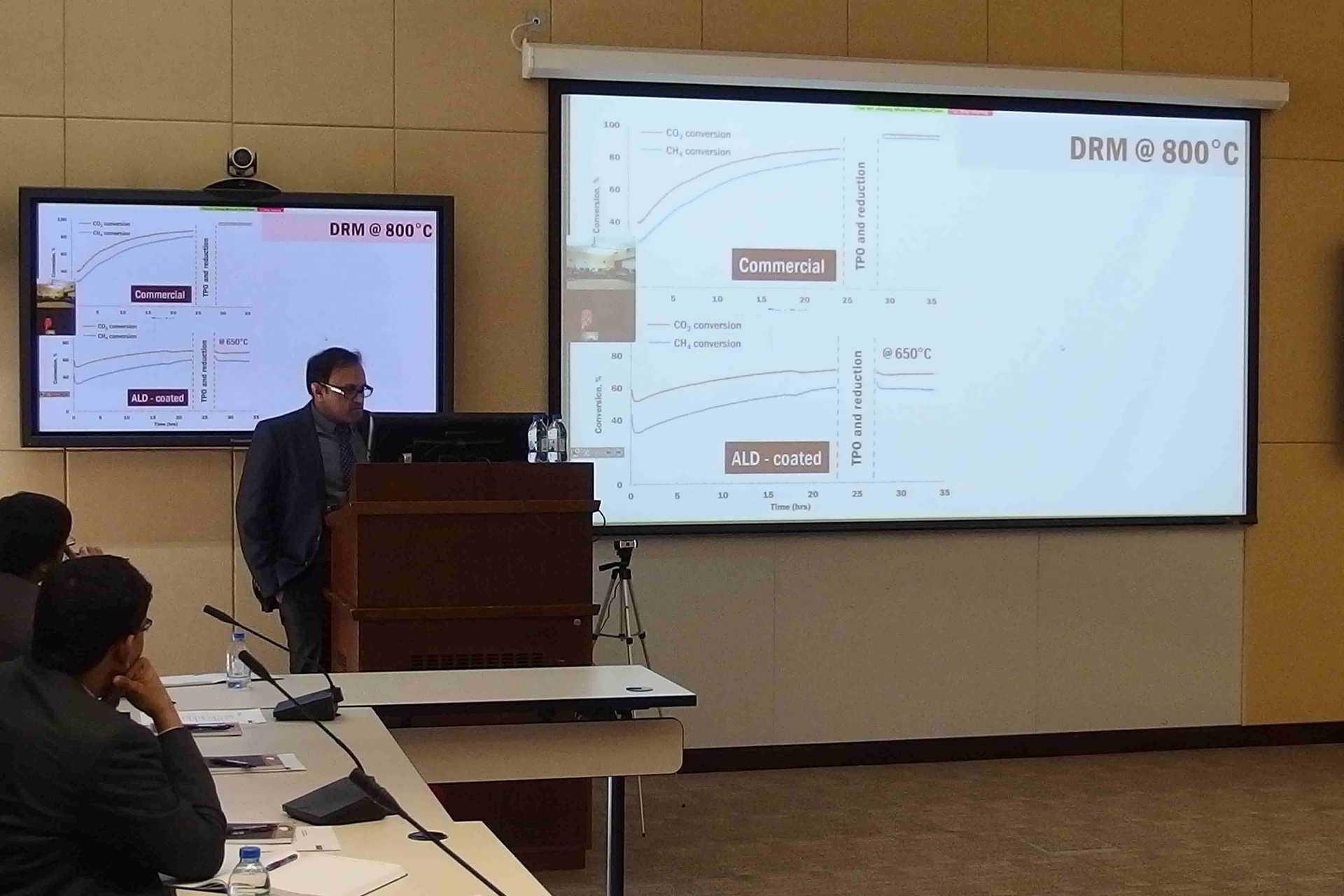

1. Afzal, S., Prakash, A., Elbashir, N. “Coking and Sintering Resistance of ALD Catalyst for Dry Reforming of Methane”. 2nd Natural Gas Utilization Workshop (Texas, Aug 12-14, 2018)

2. Afzal, S., Sengupta, D., El-Halwagi, M., Elbashir, N. “Optimization Approach to Reduction of CO2 Emissions for Syngas Production”. 2nd Natural Gas Utilization Workshop (Texas, Aug 12-14, 2018)

3. Prakash, A.; Afzal, S.; Chatla, A.; Littlewood P.; Catherin, N.; Stair, P.; Elbashir, N. (2018) “ Investigating ALD-Coated, Industrially Relevant, Nickel Reforming Catalysts” 3rd Syngas Convention (Cape Town, South Africa, March 2018)

4. Elbashir, N. (2018) “ CO2 utilization through the Dry Reforming of Methane Process” Qatar Foundation Annual Research Conference ’18 (Doha, Qatar, March 2018)

5. S. Afzal, D. Sengupta, M. M. El-Halwagi and N. O. Elbashir (2017) “Techno-Economic Assessment of Dry Reforming of Methane Process” 2017 Annual American Institute of Chemical Engineers Meeting (Minneapolis, MN, USA, Nov. 2017)

6. M.S. Challiwala, M.M. Ghouri, D. Sengupta, M.M. El-Halwagi, N.O. Elbashir (2017) “A Process Integration Approach to the Optimization of CO2 Utilization via Tri-Reforming of Methane” 2017 Annual American Institute of Chemical Engineers Meeting (Minneapolis, MN, USA, Nov. 2017)

7. M.M. Ghouri, N.O. Elbashir (2017) “ DFT study of DRM reaction on pure Ni and transition metal overlayer deposited Ni surfaces” 2017 Annual American Institute of Chemical Engineers Meeting (Minneapolis, MN, USA, Nov. 2017)

8. Prakash, A.; Littlewood P.; Guyonnet E.; Afzal, S.; Choudhury, H; Elbashir, N.(2017) “ Investigation into the superior coking resistance of ALD-coated, Nickel-based reforming catalysts” 2017 Annual American Institute of Chemical Engineers Meeting (Minneapolis, MN, USA, Nov. 2017)

9. Littlewood, P; Liu, M.; Weitz, E.; Marks, T. J.; Stair, P. C. (2017) “Modification of Ni Catalysts by Atomic Layer

10. Beltran S.P.; Balbuena, P. (2017) “Computational study of the dry reforming reaction on overcoated Ni/Al2O3 catalysts: a promising route for CO2 mitigation” 2nd international computational science and engineering conference (Doha, Qatar, 23 October 2017)

11. M.M. Ghouri, N.O. Elbashir (2017) “Density Functional Theory study of Dry Reforming of Methane on pure Nickel as well as transition metal overlayer deposited on Nickel surfaces” 2nd international computational science and engineering conference (Doha, Qatar, 23 October 2017)

12. Prakash, A.; Elbashir, N. (2017) “Designing Future Gas Processing Technology: Environmental, Efficiency and Product Design Challenges” Joint Symposium on Research Activities in Qatar hosted by Qatar University, Texas A&M University at Qatar, Hamad Bin Khalifa University (Qatar University, Doha, Qatar, October 2017)

INVITED TALKS:

1. Invited talk to Shell Houston R&D Research Center

Topic: Natural Gas Processing Research at Texas A&M University

Houston, Texas. July 19, 2018.

2. Invited talk to the World Congress Climate Change 2018 “Impact & Responses.”

Topic: Utilization of CO2 And Its Potential To Produce Ultra-Clean Fuels & Chemicals

Rome, Italy. September 13-15th, 2018,

3. Invited seminar to the Gas Processing Research Center of Qatar University

Topic: Gas Processing Technology in Qatar: potentials and challenges

GPC, Qatar University, Doha, November 15th, 2018

4. Invited talk to BASF Catalysts LLC

Topic: Design of Novel CO2 Utilization Technology for the Natural Gas Processing Plants

BASF R&D Catalysts Headquarter, New Jersey, December 2018.

5. Invited Seminar Laboratoire Catalyse & Spectrochimie (LCS) ENSICAEN – CNRS

Topic: A Path to Design Novel GTL Technology

LCS, CNRS, Caen, France, May 2017.

6. Invited talk to Aristotle University of Thessaloniki (CERTH),

Topic: Gas Processing Research at Texas A&M

Thessaloniki, Greece, April 2017.

7. Invited Seminar (Professor Paul Barton) the Chemical Engineering Department at the Massachusetts Institute of Technology (MIT)

Topic: Technology for Natural Gas Utilization

Building 66, MIT, Boston, USA, April 2017.

POSTER PRESENTATIONS:

1. Afzal, S., Prakash, A., Sengupta, D., El-Halwagi, M., Elbashir, N. “CO2 Utilization through the Dry Reforming of Methane Process”. 2nd Natural Gas Utilization Workshop (Texas, Aug 12-14, 2018)

2. Afzal, D. Sengupta, M. M. El-Halwagi and N. O. Elbashir, “CO2 utilization through the Dry Reforming of Methane Process”, 3rd Syngas Convention, Cape Town, South Africa, March 2018

3. Prakash, A.; Afzal, S.; Chatla, A.; Littlewood P.; Stair, P.; Elbashir, N., “Investigation into the superior coking resistance of ALD-coated, Nickel-based reforming catalysts”, Bukur Catalysis Reaction and Engineering Symposium,

4. Afzal, D. Sengupta, M. M. El-Halwagi and N. O. Elbashir, “Minimizing CO2 emissions for syngas production units using Dry Reforming of Methane”, Bukur Catalysis Reaction and Engineering Symposium,

5. S. Challiwala, M.M. Ghouri, D. Sengupta, M.M. El-Halwagi, N.O. Elbashir, “A Process Integration Approach to the Optimization of CO2 Utilization via Tri-Reforming of Methane”, 27th European Symposium on Computer Aided Process Engineering – ESCAPE 27, October 1st – 5th, 2017, Barcelona, Spain

6. Afzal, D. Sengupta, M. M. El-Halwagi and N. O. Elbashir, “Minimizing CO2 emissions for syngas production units using Dry Reforming of Methane”, 27th European Symposium on Computer Aided Process Engineering – ESCAPE 27, October 1st – 5th, 2017, Barcelona, Spain

PATENTS / INVENTION DISCLOSURES

Status: Invention Disclosure being processed by QF IPTT

2. Title: Highly stable Copper-Nickel alloyed catalyst for CO2 reforming of Methane:

Status: Invention Disclosure being processed by QF IPTT

3. Title: Syngas Production with high H2/CO ratio and reduced CO2 emissions and operating costs using Dry Reforming Process

Application No. 62/652,110 filed on April 3, 2018

QF ref. No. 2018-014

4. Title: System and method for carbon and syngas production.

Patent number : 62/481,100

Filed

Attorney docket

MANUSCRIPTS (IN PREPARATION)

1. Title: Investigating ALD coated Industrial Reforming catalyst- Activity studies

2. Title: Enhanced CO2 fixation and Syngas production using a two reactor setup

3. Title:

4. Title: Density Functional Theory studies on novel Cu-Ni bimetallic catalysts and their performance for Dry

MANUSCRIPTS (SUBMITTED)

1. Littlewood, E. Weitz, T. J. Marks

2. Littlewood, S. Liu, E. Weitz, T. J. Marks

TRAININGS FOR GRADUATE STUDENTS

1. One graduate student (Omar

2. Two MS Chemical engineering graduate students (Aya Absrafa, Nosaiba Mohamed) are being trained on